Inventory management

arMHAzena® WMS operates entirely on a cloud platform in its Full and Box versions.

arMHAzena® WMS (Warehouse Management System), the MHA’s complete web application, was specially designed to handle all operations in the logistics chain.

Developed and maintained by MHA, it is much more than an excellent inventory management tool (WMS): it is a supply chain management tool as a whole.

In addition, it has been a 100% web product since 2006, entirely designed within the concept of cloud (cloud computing), which facilitates the implementation and use of the system, with a significant reduction in project and maintenance costs.

A non-customizable tool, but configurable, the arMHAzena® WMS can manage multiple sites simultaneously and from remote locations,

using a single server and database.

It facilitates and streamlines the management of the entire supply chain, especially in inventory management and process traceability. Deployable in modules, it provides vertical growth scalability, ensuring a quick return on your investment.

- Entrance

- Scheduling

- Receipt

- PBL Management

- Cross-docking

- Identification

- Storage

- Handling

- Inventory

- Picking / packing

- Voice picking

- Picking

- Conference

- Resupply

- Entrance

- Scheduling

- Receipt

- PBL Management

- Cross-docking

- Identification

- Storage

- Handling

- Inventory

- Picking / packing

- Voice picking

- Picking

- Conference

- Resupply

- Production appointment

- Workflow, approval

- Supply management

- Shipping

- Queries / reports

- Audit

- Delivery control

- Structural management

- Radiofrequency / conveyor belts and stacker cranes

- Mapping and 3D design of structures and storage locations

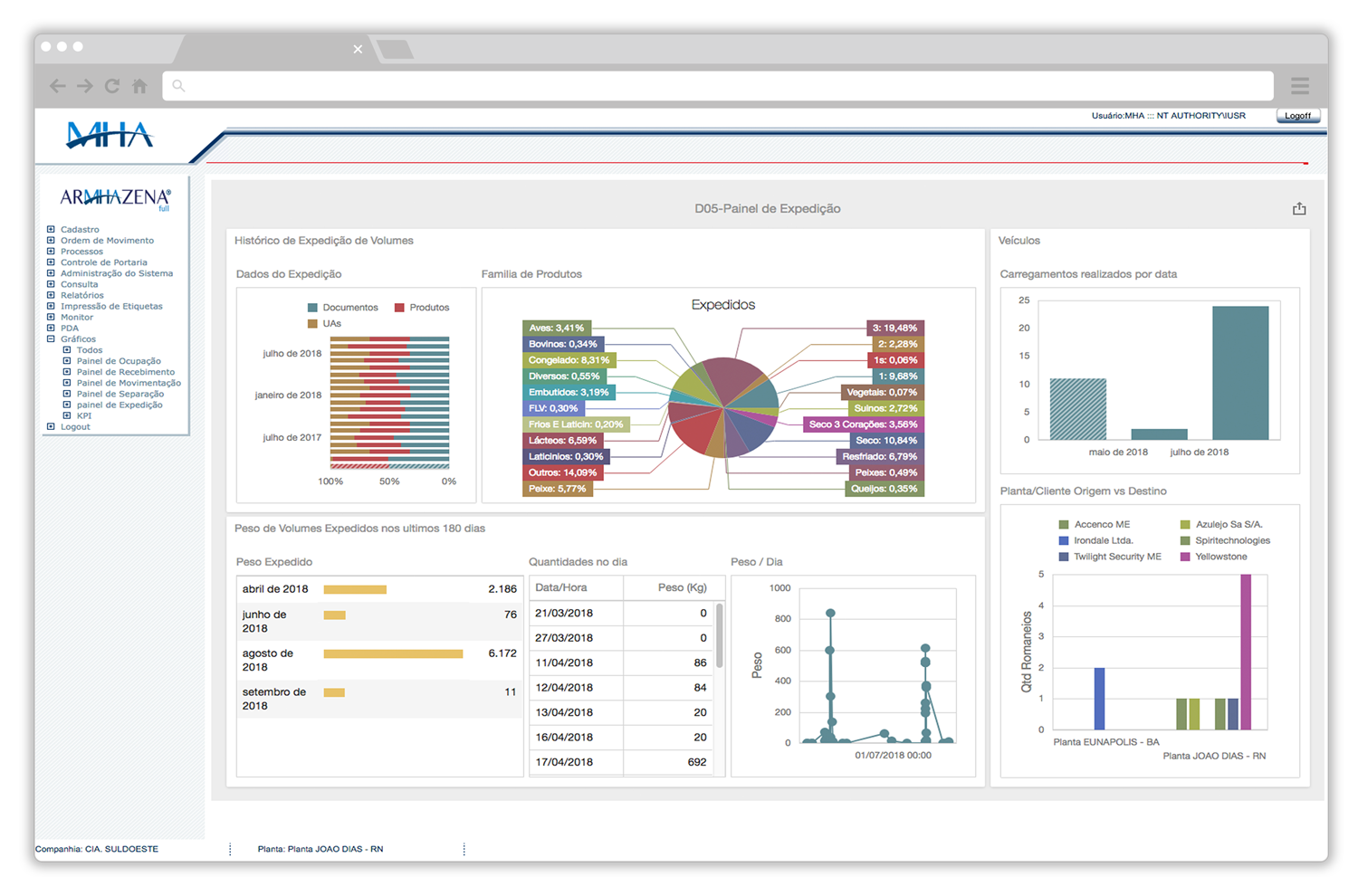

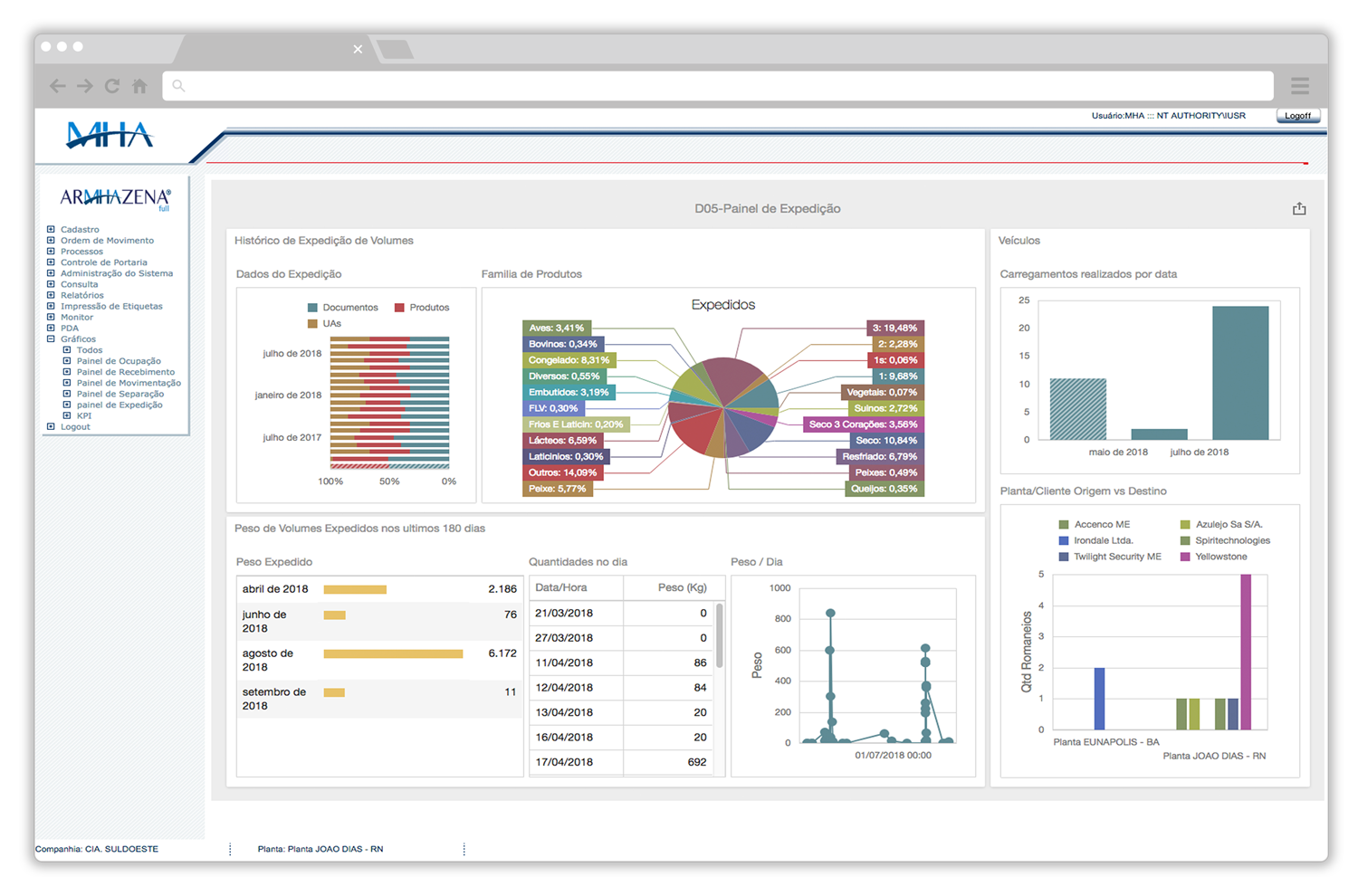

- BI with the extraction of analytical data from the operation

- SEFAZ NF-e interface

- Production appointment

- Workflow, approval

- Supply management

- Shipping

- Queries / reports

- Audit

- Delivery control

- Structural management

- Radiofrequency / conveyor belts and stacker cranes

- Mapping and 3D design of structures and storage locations

- BI with the extraction of analytical data from the operation

- SEFAZ NF-e interface

- Control of entrance and docks on receipt

- Management of delivery or collection schedules

- Issuance of product identification labels

- Choice of address by the system

- Confirmation of product storage

- Cross-docking

- Product relocation

- Resupply of picking addresses

- Purchasing and replenishment in the supply chain

- Inventory traceability by balance, replenishment, and reserve across the entire supply chain

- Check locations and balances

- Validity control (shelf life)

- Deadline control (FIFO / FEFO / LIFO)

- Batch control for traceability

- Product reservations for orders

- Smart separation and option to use voice module

- Output of products / check and shipping

- Loading

- Control of entrance and docks on receipt

- Management of delivery or collection schedules

- Issuance of product identification labels

- Choice of address by the system

- Confirmation of product storage

- Cross-docking

- Product relocation

- Resupply of picking addresses

- Purchasing and replenishment in the supply chain

- Inventory traceability by balance, replenishment, and reserve across the entire supply chain

- Check locations and balances

- Validity control (shelf life)

- Deadline control (FIFO / FEFO / LIFO)

- Batch control for traceability

- Product reservations for orders

- Smart separation and option to use voice module

- Output of products / check and shipping

- Loading

- Active summons

- Kitting

- Traceability of stocked products

- Product addressing (optimization of space and handling)

- Information on the entire process in real-time

- Speed and reliability of automatically collected data

- Reduction of errors in operation, inventory counting (inventory), and data entry

- Visualization of internal processes

- Productivity management: reports

- Load groupage

- Exploitation the 3rd dimension

- Dynamic storage structures

- Interface with handling equipment

- Automation of treadmills, scales, data collectors, voice equipment, printers, antennas, and RFID readers

- Interface with SEFAZ, generation, and validation of NF-e and CT-e transport

- Productivity KPI

- Active summons

- Kitting

- Traceability of stocked products

- Product addressing (optimization of space and handling)

- Information on the entire process in real-time

- Speed and reliability of automatically collected data

- Reduction of errors in operation, inventory counting (inventory), anddata entry

- Visualization of internal processes

- Productivity management: reports

- Load groupage

- Exploitation the 3rd dimension

- Dynamic storage structures

- Interface with handling equipment

- Automation of treadmills, scales, data collectors, voice, equipment, printers, antennas, and RFID readers

- Interface with SEFAZ, generation, and validation of NF-e and CT-e transport

- Productivity KPI

arMHAzena® WMS, a Complete Solution

Designed with the help of the best in software engineering and written entirely using systems development and construction methodologies, the vast codified intelligence of arMHAzena® makes it a formidable technological tool when it comes to inventory management of any type: factory, wholesale, retail, general warehouse, logistic operator, health sector, agribusiness, transporters, etc.

Extremely flexible, arMHAzena® has configurable parameters that the system administrator can manage without technicians’ or programmers’ help.

With these parameters, it is possible to control changes in operation easily, create new inventory addresses, change storage structures, and manage picking flow, shipping method, checking, and reports, to mention some of the functionalities open to configuration.

In addition, as it is an entirely web-based system, arMHAzena® enables inventory management to be carried out remotely, simply by having Internet access. In this way, any operation and inventory information can be provided by you to your customers and suppliers whenever you deem convenient and very practical, at any time and in any place.

MHA has solid experience of more than 18 years in the logistics area, constantly developing and implementing WMS and supply chain management systems.

It is the leader in the number of active sites managed in Brazil, thanks to the vast knowledge it has accumulated over the years in the preparation and execution of projects focused on logistics. MHA’s highly qualified and experienced consultants will undoubtedly make a difference with your company’s team.

Performance Verticals

Health

Wholesaler

Retail

Logistics operator / Service provider

Agribusiness

Manufacturer and Factory

Rules by Performance Verticals

- Health

- Wholesaler

- Retail

- Logistics operator / Service provider

- Builders

- Agribusiness

- Manufacturer and Factory

- Carriers

Widely used by companies in the healthcare area, such as hospitals, care clinics, distributors of medicines, and various supplies, arMHAzena® stands out in this area for the flexibility and scope with which it can manage not only the inventory itself but also the entire supply chain, ensuring the traceability of items and processes throughout.

- Drug control by serialization

- Drug control by randomization

- Control of hospital items

- Placebo control

- Drug dispensing management

- Resupply management of the entire consumption chain

- Online requests

- Traceability of classified drugs

- Approval flow according to requests

- Direct interface with HMS

- Automatic replenishment interface between inventories

- Control and management of service revenues

- Reverse logistics operation

- Batch item control

Widely used by companies in the healthcare area, such as hospitals, care clinics, distributors of medicines, and various supplies, arMHAzena® stands out in this area for the flexibility and scope with which it can manage not only the inventory itself but also the entire supply chain, ensuring the traceability of items and processes throughout.

- Drug control by serialization

- Drug control by randomization

- Control of hospital items

- Placebo control

- Drug dispensing management

- Resupply management of the entire consumption chain

- Online requests

- Traceability of classified drugs

- Approval flow according to requests

- Direct interface with HMS

- Automatic replenishment interface between inventories

- Control and management of service revenues

- Reverse logistics operation

- Batch item control

MHA is very well aware of the unique characteristics and demands of the wholesale sector, where the large volume of buying and selling, as well as the volume of inventory and its turnover speed, makes the wholesaler’s inventory management processes, to some extent, very similar to those of other sectors, such as supermarkets and retailers, for example. However, the wholesale operation requires a different treatment from the inventory management system. It is necessary to separate items with similar codes or even the same, but from different manufacturers, and the management system needs to be focused mainly on inputs, outputs, and the high volume of fractionated separation.

With arMHAzena®, you as a wholesaler can interconnect your company’s ERP with order management and automatic inventory replenishment, as well as manage partial deliveries with the supplier and make the inventory position available to the end customer; it can also receive orders with inventory reservation validation, linked to the ERP, for credit approval and item separation; it can also control the opening and closing of orders via the WMS, through the call center and online sales service.

- Management of multiple items with the same code

- Management of similar items with different storage structures

- Order management with the supplier

- Purchasing supply management

- Kitting management

- Shipping management by delivery route

- Delivery and collection scheduling management

- Online orders via the web, directly linked to the approval and inventory area

- Picking of orders linked to the company’s call center, with orders opening and closing

- Customized conference for fractionated items in large volume

- Merge orders by addressing downscaling

MHA is very well aware of the unique characteristics and demands of the wholesale sector, where the large volume of buying and selling, as well as the volume of inventory and its turnover speed, makes the wholesaler’s inventory management processes, to some extent, very similar to those of other sectors, such as supermarkets and retailers, for example. However, the wholesale operation requires a different treatment from the inventory management system. It is necessary to separate items with similar codes or even the same, but from different manufacturers, and the management system needs to be focused mainly on inputs, outputs, and the high volume of fractionated separation. With arMHAzena®, you as a wholesaler can interconnect your company’s ERP with order management and automatic inventory replenishment, as well as manage partial deliveries with the supplier and make the inventory position available to the end customer; it can also receive orders with inventory reservation validation, linked to the ERP, for credit approval and item separation; it can also control the opening and closing of orders via the WMS, through the call center and online sales service.

- Management of multiple items with the same code

- Management of similar items with different storage structures

- Order management with the supplier

- Purchasing supply management

- Kitting management

- Shipping management by delivery route

- Delivery and collection scheduling management

- Online orders via the web, directly linked to the approval and inventory area

- Picking of orders linked to the company’s call center, with orders opening and closing

- Customized conference for fractionated items in large volume

- Merge orders by addressing downscaling

Retail is an area with unique characteristics, in which the need for agility in supply and efficiency in managing a high volume of inventory requires a complete logistics operation focused not only on inventory control but also on supply chain management.

The easily configurable parameterizations of the arMHAzena® WMS according to retail rules make it possible for the system to continuously adapt to the logistical evolution of the area, which is constantly changing, depending on factors such as high or low consumption, expansion of service networks or the need to manage new supply items every month.

By implementing arMHAzena® in your business, retailers can easily manage the logistics management of the entire supply chain, controlling distribution centers, inventory held by third parties, and supply to stores or branches; it is also able to manage transport on delivery or collection, as well as requests and approvals online, and even has a panoramic and real-time view of inventory and replenishment levels, in addition to the entire e-commerce operation within the inventory.

- Multiple inventory management

- Third-party inventory management

- Supply chain management

- Management of dry, chilled, frozen, and FV (fruits and vegetables) items

- Transport management

- Cost management by logistics contract

- Damage management

- Reverse logistics operation

- e-commerce inventory management

- Inventory management of branches or franchised stores

- Control of kits and promotional items

- Control of items by grid

- On-demand supply management

- Item management by collection

- Control of items by serial or batch

- RFID item management

Retail is an area with unique characteristics, in which the need for agility in supply and efficiency in managing a high volume of inventory requires a complete logistics operation focused not only on inventory control but also on supply chain management.

The easily configurable parameterizations of the arMHAzena® WMS according to retail rules make it possible for the system to continuously adapt to the logistical evolution of the area, which is constantly changing, depending on factors such as high or low consumption, expansion of service networks or the need to manage new supply items every month.

By implementing arMHAzena® in your business, retailers can easily manage the logistics management of the entire supply chain, controlling distribution centers, inventory held by third parties, and supply to stores or branches; it is also able to manage transport on delivery or collection, as well as requests and approvals online, and even has a panoramic and real-time view of inventory and replenishment levels, in addition to the entire e-commerce operation within the inventory.

- Multiple inventory management

- Third-party inventory management

- Supply chain management

- Management of dry, chilled, frozen, and FV (fruits and vegetables) items

- Transport management

- Cost management by logistics contract

- Damage management

- Reverse logistics operation

- e-commerce inventory management

- Inventory management of branches or franchised stores

- Control of kits and promotional items

- Control of items by grid

- On-demand supply management

- Item management by collection

- Control of items by serial or batch

- RFID item management

To meet especially the needs and demands of the logistics operations sector, with all the complex issues related to the provision of services which characterize it, MHA made the arMHAzena® product an intelligent and flexible tool, capable of meeting all the rules required by the sector.

- Operation control held by the customer

- Deposit control held by third parties

- Contract-bound billing rules

- Customer service provision rules

- Transformation rules held by third parties

- Control rules for perishables (including frozen and chilled)

- Drug control rules

- Control of transport, collection, and delivery

- NF-e generation and control

- Direct integration with SEFAZ

- Billing management by contract rule.

To meet especially the needs and demands of the logistics operations sector, with all the complex issues related to the provision of services which characterize it, MHA made the arMHAzena® product an intelligent and flexible tool, capable of meeting all the rules required by the sector.

- Operation control held by the customer

- Deposit control held by third parties

- Contract-bound billing rules

- Customer service provision rules

- Transformation rules held by third parties

- Control rules for perishables (including frozen and chilled)

- Drug control rules

- Control of transport, collection, and delivery

- NF-e generation and control

- Direct integration with SEFAZ

- Billing management by contract rule.

arMHAzena® is capable of managing the numerous items that enter the different phases of work and controlling the work’s support warehouse.

With the arMHAzena® inventory management system, the user can control the cubic meters (m3) of cement, stone, and sand used; the transformation into concrete or even the ready-made concrete used in work; the amount of steel, iron, screws, forms, safety items and all the equipment used in civil construction. In this way, arMHAzena® provides the construction manager with all the traceability of items consumed by area, floor, user, or outsourced company, and the costs of each construction process by consumption management, using a cost center.

In addition to controlling inventory items, whose traceability arMHAzena® can carry out, the system also provides management and control of productivity according to the labor used, both internal labor and that of a hired outsourced company. All processes are registered and managed to control each company’s or service provider’s productivity within the work and the actual cost per hour of service and/or machinery involved in the indicated process.

arMHAzena® manages to detail, whether by cost center, building unit, or area of work, all the inventory items and equipment used by its professionals, calculating the costs of each process performed.

- Inventory management of construction items

- Warehouse management

- Consumption control by cost center

- Consumption control by building and floor

- Management of third parties involved in the work

- Management of equipment used on site

- Productivity control by resource

- Cost control per activity performed

- Workflow rules in approving requests

- Management of consumption requests by cost center

arMHAzena® is capable of managing the numerous items that enter the different phases of work and controlling the work’s support warehouse.

With the arMHAzena® inventory management system, the user can control the cubic meters (m3) of cement, stone, and sand used; the transformation into concrete or even the ready-made concrete used in work; the amount of steel, iron, screws, forms, safety items and all the equipment used in civil construction. In this way, arMHAzena® provides the construction manager with all the traceability of items consumed by area, floor, user, or outsourced company, and the costs of each construction process by consumption management, using a cost center.

In addition to controlling inventory items, whose traceability arMHAzena® can carry out, the system also provides management and control of productivity according to the labor used, both internal labor and that of a hired outsourced company. All processes are registered and managed to control each company’s or service provider’s productivity within the work and the actual cost per hour of service and/or machinery involved in the indicated process.

arMHAzena® manages to detail, whether by cost center, building unit, or area of work, all the inventory items and equipment used by its professionals, calculating the costs of each process performed.

- Inventory management of construction items

- Warehouse management

- Consumption control by cost center

- Consumption control by building and floor

- Management of third parties involved in the work

- Management of equipment used on site

- Productivity control by resource

- Cost control per activity performed

- Workflow rules in approving requests

- Management of consumption requests by cost center

arMHAzena® WMS is a handy tool in the agribusiness sector. Whether managing the inventory of grains, fertilizers, or agrochemicals or controlling agricultural machinery, inventory of parts, or veterinary products, the truth is that with arMHAzena®, large producers and cooperatives will soon feel the difference in cost reduction and increased productivity, results from better organization of the supply chain.

When storing grains, arMHAzena® controls by the cubic meter (m3), weight, or weight conversion to stored bags. Suppose storage is in bulk and inside storage silos. In that case, arMHAzena® communicates with the silo’s weight controllers and converts the stored grain measure from weight to consumption bag, which gives the producer a real vision of the amount of grain in bags still inside the storage silo.

In the management of products such as fertilizers and agrochemicals, as well as insecticides and various poisons, arMHAzena® makes it possible to trace the batch and the validity of each item and organizes the reverse logistics of the bottles, with strict control of the batches for destruction. By the way, in the general aspect of shelf life, arMHAzena® provides complete traceability, from the manufacturer to the reverse logistics of the package.

For the processes of the distribution center or inventory of parts and agricultural machinery, arMHAzena® uses the same rules aimed at the wholesale distributor but with particularities in the assembly and disassembly of machines and consumption of parts, as well as in the assembly of kits and control of SKUs (stock keeping units) per pack.

Finally, in the pharmacy and inventory of veterinary products, arMHAzena®, in addition to focusing on batches and expiry dates, maintains the traceability of products from the manufacturer to the end customer. In this way, the inventory manager can accurately track the medicine until final consumption, even knowing which animal it was administered to and which dose was applied, for example.

- Grain management and storage in silos

- Grain control by weight, bag, and cubic meter (m3)

- Management of fertilizers, agrochemicals, and insecticides

- Management of spare parts and agricultural machinery

- Veterinary drug and product management

- Seed inventory management

arMHAzena® WMS is a handy tool in the agribusiness sector. Whether managing the inventory of grains, fertilizers, or agrochemicals or controlling agricultural machinery, inventory of parts, or veterinary products, the truth is that with arMHAzena®, large producers and cooperatives will soon feel the difference in cost reduction and increased productivity, results from better organization of the supply chain.

When storing grains, arMHAzena® controls by the cubic meter (m3), weight, or weight conversion to stored bags. Suppose storage is in bulk and inside storage silos. In that case, arMHAzena® communicates with the silo’s weight controllers and converts the stored grain measure from weight to consumption bag, which gives the producer a real vision of the amount of grain in bags still inside the storage silo.

In the management of products such as fertilizers and agrochemicals, as well as insecticides and various poisons, arMHAzena® makes it possible to trace the batch and the validity of each item and organizes the reverse logistics of the bottles, with strict control of the batches for destruction. By the way, in the general aspect of shelf life, arMHAzena® provides complete traceability, from the manufacturer to the reverse logistics of the package.

For the processes of the distribution center or inventory of parts and agricultural machinery, arMHAzena® uses the same rules aimed at the wholesale distributor but with particularities in the assembly and disassembly of machines and consumption of parts, as well as in the assembly of kits and control of SKUs (stock keeping units) per pack.

Finally, in the pharmacy and inventory of veterinary products, arMHAzena®, in addition to focusing on batches and expiry dates, maintains the traceability of products from the manufacturer to the end customer. In this way, the inventory manager can accurately track the medicine until final consumption, even knowing which animal it was administered to and which dose was applied, for example.

- Grain management and storage in silos

- Grain control by weight, bag, and cubic meter (m3)

- Management of fertilizers, agrochemicals, and insecticides

- Management of spare parts and agricultural machinery

- Veterinary drug and product management

- Seed inventory management

Aiming to help companies that manufacture, assemble, and disassemble products or provide finishing services, the arMHAzena® WMS not only operates inventory management but also controls the production line in its entirety, that is, from the raw material up to the recording of the production order, passing through the supply of the production line.

arMHAzena® guarantees the traceability of the batches used, recording validity, supplier (according to the type of raw material), return to inventory of surplus production lines, movement of raw material from line to line, and communication with the production order, passing on to the user the information of the lots and items consumed.

Furthermore, arMHAzena® has unique characteristics within the production chain for controlling the premix area, covering the production line for assembling kits, management of consumption of input inventory, and traceability of items consumed within the premix assembly.

At the end of the production line, arMHAzena® records all the manufactured items and updates the MRP or ERP regarding the items produced in each line, automatically canceling the production order, and including all the identification of the items and their packaging.

Managing finished product items within the inventory is now treated as standard inventory management, with receipt, storage, inventories, separation, checking, and shipping. The configuration rules for each process, however, are always determined according to the logistical needs of each customer.

- Management of all raw material inventory

- Production control and traceability of the premix area

- Control and automatic capture of weight on scales

- Quality management and item locks by quality

- Supply and traceability on the production line

- Recording and writing off the production order

- Identification of items and packaging in the production appointment

- Finished product inventory management

- Finished product delivery logistics management

- Third-party management in finished product management

Aiming to help companies that manufacture, assemble, and disassemble products or provide finishing services, the arMHAzena® WMS not only operates inventory management but also controls the production line in its entirety, that is, from the raw material up to the recording of the production order, passing through the supply of the production line.

arMHAzena® guarantees the traceability of the batches used, recording validity, supplier (according to the type of raw material), return to inventory of surplus production lines, movement of raw material from line to line, and communication with the production order, passing on to the user the information of the lots and items consumed.

Furthermore, arMHAzena® has unique characteristics within the production chain for controlling the premix area, covering the production line for assembling kits, management of consumption of input inventory, and traceability of items consumed within the premix assembly.

At the end of the production line, arMHAzena® records all the manufactured items and updates the MRP or ERP regarding the items produced in each line, automatically canceling the production order, and including all the identification of the items and their packaging.

Managing finished product items within the inventory is now treated as standard inventory management, with receipt, storage, inventories, separation, checking, and shipping. The configuration rules for each process, however, are always determined according to the logistical needs of each customer.

- Management of all raw material inventory

- Production control and traceability of the premix area

- Control and automatic capture of weight on scales

- Quality management and item locks by quality

- Supply and traceability on the production line

- Recording and writing off the production order

- Identification of items and packaging in the production appointment

- Finished product inventory management

- Finished product delivery logistics management

- Third-party management in finished product management

With the evolution of logistics within the transport area, many carriers no longer perform only inbound and outbound (collection and delivery), starting also to manage their customers’ inventory as service providers in storage and distribution.

arMHAzena® WMS, in turn, was born managing transport logistics, taking care of the traceability of collection, delivery, knowledge management, and freight. In this way, it added the rules already used in logistical operations to provide services (logistics operators) to the carrier area. The result was that carriers that already used arMHAzena® in knowledge and freight management now have all the logistics operator rules available in the same product and began to serve a broader range of activities, adding services to the operation through the management of the system.

Carriers that use arMHAzena® in logistics management benefit from the supply chain rules already built into the system. With these rules, in addition to managing the entire inventory in a satisfactory and detailed manner, they can also address the whole supply chain, controlling deliveries, collections, knowledge, inventory held by third parties, provision of services by third parties, or added to the operation, freight control, management of the fleet used, management of the productivity of resources and machines involved in the process, etc.

- Collection and delivery management

- Issuance of electronic knowledge

- Freight control

- Fleet control and third-party aggregation

- Logistics operator inventory management (WMS)

- Billing management by the rule of service provision and contracts

- Third-party inventory management

- Supply chain traceability management

With the evolution of logistics within the transport area, many carriers no longer perform only inbound and outbound (collection and delivery), starting also to manage their customers’ inventory as service providers in storage and distribution.

arMHAzena® WMS, in turn, was born managing transport logistics, taking care of the traceability of collection, delivery, knowledge management, and freight. In this way, it added the rules already used in logistical operations to provide services (logistics operators) to the carrier area. The result was that carriers that already used arMHAzena® in knowledge and freight management now have all the logistics operator rules available in the same product and began to serve a broader range of activities, adding services to the operation through the management of the system.

Carriers that use arMHAzena® in logistics management benefit from the supply chain rules already built into the system. With these rules, in addition to managing the entire inventory in a satisfactory and detailed manner, they can also address the whole supply chain, controlling deliveries, collections, knowledge, inventory held by third parties, provision of services by third parties, or added to the operation, freight control, management of the fleet used, management of the productivity of resources and machines involved in the process, etc.

- Collection and delivery management

- Issuance of electronic knowledge

- Freight control

- Fleet control and third-party aggregation

- Logistics operator inventory management (WMS)

- Billing management by the rule of service provision and contracts

- Third-party inventory management

- Supply chain traceability management

Solicite uma Demonstração

Preencha o formulário abaixo para entrar em contato.